SyncusTech has built an R&D consortium with the Korea Testing Certification, the University of Suwon, and three leading computer industry companies. Allowing us to test our products in a wide range of environments and conditions, thus helping us improve performance. The allocation of this grant will focus on international development to meet the growing needs in the global market.

The 2015-2017 KIAT Award

Through the Korea Institute for the Advancement of Technology (KIAT) provides resources to ensure the transfer of technology across industries and institutions, R&D programs in the private sector, and international strategic development (EU, USA, Asia). Every year, KIAT selects a limited number of qualified manufacturers for exceptional funding. The funds will be dedicated to improve the reliability and performance of export products, including the Global market.

A Technology Consortium Led By SyncusTech

SyncusTech has been awarded a $700,000 grant to develop and lead a 2-year project. The project’s goal is to strengthen the reliability of our industrial computer motherboards on a global scale. To achieve the goals of this project, we had built a technical consortium. We then tested, analyzed, and improved the vulnerable parts of our measuring and controls systems. The three components that were of highest priority during this project were the motherboards, chassis, and power modules.

- CPU: Intel® Atom™ Processor E3845/E3826/3815

- Dimension: EPIC SBC (165mm x 115 mm)

- Memory: 1xDDR3L SO-DIMM support up to 8GB

- Storage: SATA II 3GB/s

- Expansion: 1 x PCIe x16 Generation 3 lane, 1x mPCIe / mSATA selectable

- Low Temperature Step Stress Test

- High Temperature Step Stress Test

- Vibration Step Stress Test

- Combined Thermal Shock and

Vibration Test - M/B Module Life Test

- Power Module Life Test

- M/B Module Low Temperature Test

- M/B Module Thermal Shock Test

- Power Module Low Temperature Test

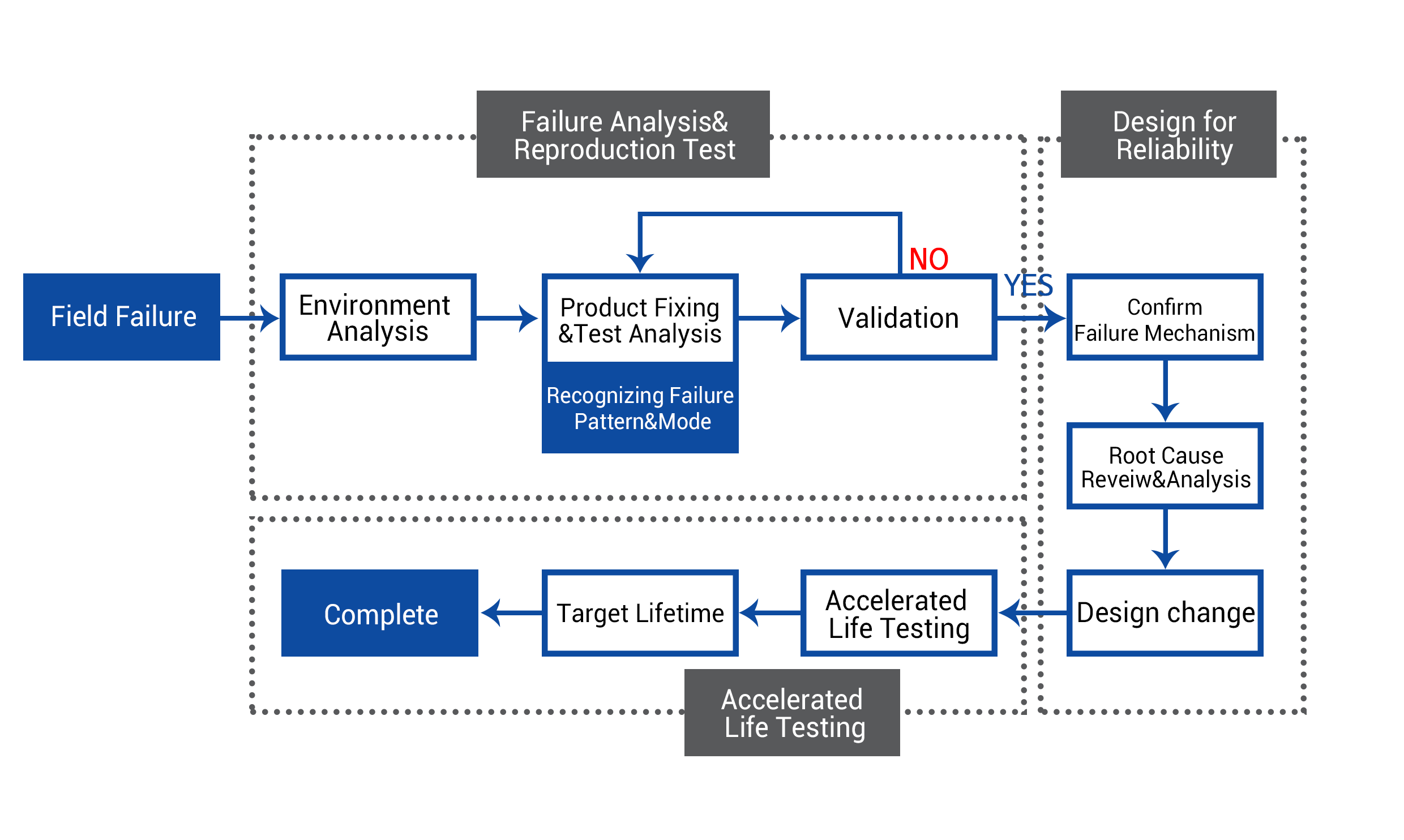

There was difficulty in identifying areas of failures that occurred after the application performed over a long period of time in the field. The product, delivered to a user after being released, requires a failure analysis technique whereby the exact cause of long term defects can be identified. Furthermore, identification of exact causes and reliable prediction of the product lifetime were lacking. By virtue of the spread of reliability technology, a HALT TEST is performed to precisely identify issues. For more information, please refer to Reliability Test Report section 3.2 HALT TEST.